Objective

The aim of the Reuse-LCA project is to fill the current gaps in knowledge about the reuse of construction

components in Switzerland in order to better understand and exploit its environmental potential.

To achieve this, the project has two main focuses:

● Assessing the environmental benefits of reuse: This involves quantifying the reduction in greenhouse

gas (GHG) emissions made possible by reuse.

● Optimising the environmental aspects of reuse: The project seeks to identify best

practice for maximising the benefits of reuse, taking into account the different types of building

materials and components.

The project focuses specifically on 'today's' reuse, i.e. current reuse practices, with six 'demand-side'

case studies (i.e. buildings incorporating reused products) graphically presented in the case study

sections of this website. The project also looked at two additional case studies: one related to the

reuse of existing window frames in existing buildings (analysis including not only embodied greenhouse

gas emissions but also operational emissions and the building physics of the windows, i.e. U-value,

thermal bridging...), and one belonging to the "supply side" (i.e. a deconstruction site with concrete

reuse). These two case studies can be found in the final report of the Reuse-LCA (see link to the report

in the "About" section). Data on the case studies were collected through questionnaires sent to the

partners.

This website presents in details the reuse practices of five case studies on the "demand side" and their LCA results.

Life cycle assessment applied to building with reuse

Starting point: the swiss standards SIA 2032 and SIA 2040 are the basis for all calculations.

The functional unit is one square meter of energy reference area (m² ERA, as defined in SIA 416/1 ch. 3.2)

of a residential, office or mixed-use building providing the thermal comfort needed according to SIA 380/1 standard and

during a service life of 60 years. The building can be either a new construction or a renovation and the scope

of the calculation is therefore adapted according to SIA 2032.

The Reuse-LCA project is aligned with recent methodological recommendations in Switzerland regarding reuse in construction, including:

● The Reuse-LCA's Zurich workshop in November 2021, which led to a consensus on the ‘additional expenditures’

method for modelling reuse, based on Pfäffli's work (2020)

● The SFOE project ‘Zero net greenhouse gas emissions in the building sector’ (final report in november 2024, methodological questions F0)

which also recommends the ‘additional expenditures’ method.

● The UVEK DQRv2 database protocol of November 2023, which stipulates that disassembly,

transport and refurbishment/repair efforts are attributed to the new life cycle of the reused products and components.

● The KBOB database rules for establishing the life cycle assessment of building materials and products in

Switzerland (version 7.1, June 2024), which specify that the burdens of reused components are calculated

on the basis of transport, preparation and consolidation activities, as well as end-of-life disposal.

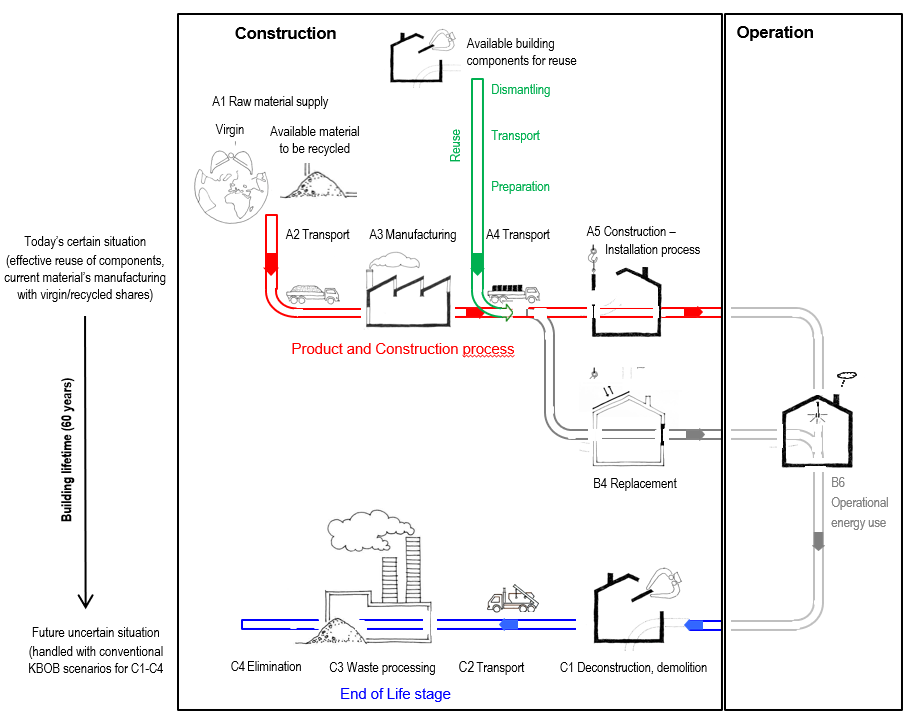

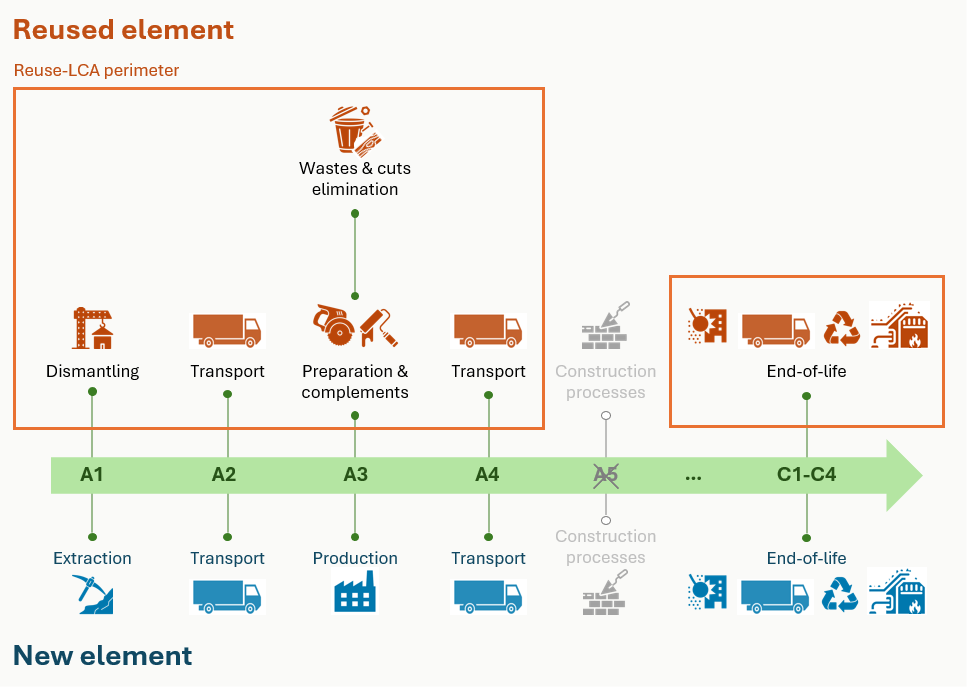

The ‘additional expenditures’ method involves taking into account all the stages in the re-use process,

from the product's end-of-life stage to its actual re-use in a new building. This includes dismantling,

transport to the storage location and workshop, storage, reconditioning activities (cleaning, etc.), as

well as necessary additions and modifications (painting, assembly, etc.).

The Reuse-LCA project adopts the ‘Construction domain’ perimeter defined by the SIA 2032 standard, which

encompasses the production phase (modules A1 to A3), the replacement phase during use (module B4) and the

end-of-life phase (modules C1 to C4). Unlike SIA 2032, the Reuse-LCA project includes transport to the

building site (module A4) in its scope of analysis, in order to assess the impact of the supply distance

of reused products and answer the crucial question: ‘What is the maximum supply distance for reused products to remain eco-efficient?’.

All reuse-related activities are taken into account until the reused components are ready for use in the

building, in the same way as new components. The preparation activities that take place on site are included in module A3 (manufacturing).

The elimination of waste and scrap materials generated during the preparation of reused components (module A3) is also included.

Furthermore, the Reuse-LCA project adresses further methodological aspects that lacked clarity in the previous recommendations and defined clear rules:

● Is the disassembly activity included in the new life cycle of the reused product? YES

● Is the inclusion of the disposal of waste, cuts and losses occurring during the preparation of reused components included? YES

● How to account for preparation activities specific to reused components that take place on the construction or renovation site? In the manufacturing stage (module A3)

● How to assess the future replacement of the reused component? Use of a new equivalent component, same as for new initial components as the future replacement is a scenario common to all components regardless of whether they are installed in the building today as virgin, recycled or reused.

● How is the new equivalent product substituted by a reused product defined ? Mostly based on material equivalency, when relevant based also on functional equivalency (e.g., for thermal insulation material, windows, and photovoltaic panels)

● Which system boundary is considered when comparing the burdens of a reused and a new product ? (Demand side perimeter)

Calculating potential reductions in GHG emissions

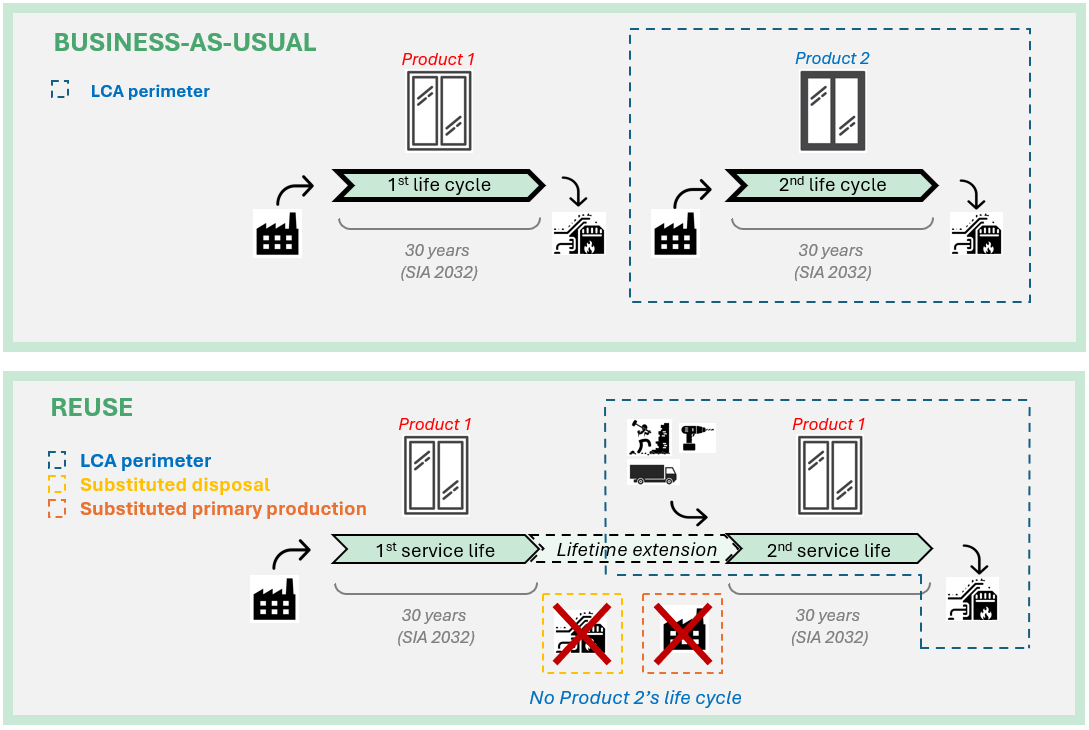

Reuse extends the life of products, thereby reducing primary production and waste management activities.

The Reuse-LCA project quantifies these potential reductions in GHG emissions by comparing the environmental

impact of the reused product with that of an equivalent new product.

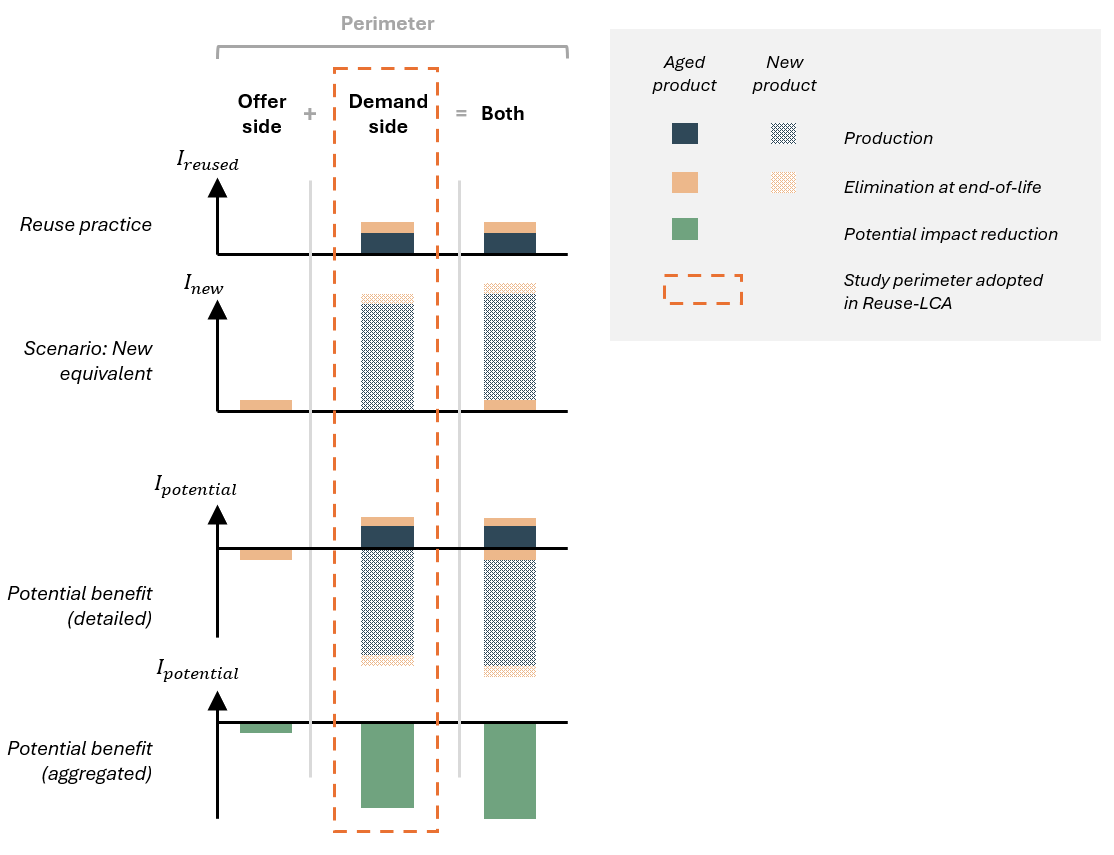

It is important to determine the scope of the analysis in order to assess emissions reductions. Two points of view are possible:

● "Offer side": from the point of view of the building from which the reused elements originate. The impact reduction corresponds to the disposal avoided.

● "Demand side": from the point of view of the building integrating the reused elements. The impact reduction corresponds to the primary production avoided.

In the Reuse-LCA project the calculation takes into account the ‘demand side’ perimeter, i.e. from the point of view of the building

that incorporates the reused product, in accordance with the selected case studies.

The comparison between a reused product and an equivalent new product is essential for calculating emissions reductions.

However, the definition of an equivalent new product can vary according to several criteria:

● Material equivalence: the new substituted product has the same material composition as the reused product

● Functional equivalence: the new substituted product offers the same functional quality or performance as the reused

product (thermal conductivity, acoustic properties, structural strength, etc.).

● Economic equivalence: The new product represents the most economical choice on the market or an average product on the market.

The Reuse-LCA project adopts a combined approach. Material equivalence is mainly used for its simplicity.

Functional equivalence is used in addition for certain specific products, such as thermal insulation, photovoltaic panels and windows.